2017 just began and the world seems to be already being subject of unprecedented and unforeseeable changes: an unexpected presidential election, ongoing instability in the worldwide economy and, as expert David Kiger stressed in previous articles, the development and rise of a sheer array of technological innovations that indeed embody the capability disrupt the well-known and accepted connotation of supply chain management, and, just as people tend to focus on their new year’s resolution as the coming year approaches, it is now time for supply chain managers to start outlining the measurements they will need to take in order for them to cope with such changes.

In fact, supply chain management leaders around the globe carried out a survey to find out whether local supply chain management executives were planning on reforming their functions. Surprisingly, a staggering 82% of supply chain management and procurement organizations confirmed that indeed they were currently undergoing, to some extent, a huge transformation. Compared to the evolution the industry has had in the past, and in spite of the fact that there have been tremendous game-changing developments, 82% is in reality an enormous figure. On average, only a third of businesses seem to be compelled by the juncture and consequently decide to undergo a transformation in regards to their supply management activities, however, in accordance with this last survey, the proportion has gone through the roof dramatically.

It would be fair to assert that many organizations within the corporate community, when it comes to supply chain management functions and activities, the major connotation is found in the realm of the least adaptive technological changes. In fact, many CPOs believe and have in fact observed throughout time that supply chain management and procurement is not as subject to change as other areas, except, obviously, when there is technology involved. David Kiger has pointed out before that given the pace at which technological developments have been occurring as of the past decade, companies and businesses have found a tremendous opportunity —since it allows them to enhance and improve their efficiency rates—, but also they seem to be struggling to keep up the pace.

Such changes demand, as a consequence, an important investment. Such investment, contrasted with the risk to which they are exposed for outsourcing their operations, seems to be somewhat fair. Historically, there have been plenty of cases where even a minor disruption or change went on to impact the global value and supply chain, causing lot of trouble. Such landscape compelled companies to be constantly aware of such exposure and understand their procurement activities as a major opportunity, and here are some words of advice on how to get the most out of this evolving era.

Assess the supply chain complexity

Procurement and supply chains might become a real nightmare, especially with recalls. In the past quintile, historically established giants like Samsung, Volkswagen, had to incur in major recalls —mobile phones, diesel engines, airbags, etc.—. And even other industries which might seem not as dependant on technology: food, pharmaceutical and playthings industries have been experiencing increasing recalls. Much of the blame is often found in the increasing complexity of supply chains and procurement outlines, since the bigger the degree of complexity the bigger the odds for accidents. Processes and organizations need to start questioning how they have been carrying out procurement activities in order to reduce and simplify their interactions. Paradoxically, companies started approaching their quest for simplicity by reducing human capital and relying on automation, consolidating suppliers and making product designs much simpler. At this point, it is of high importance for companies to spare no efforts to reduce complexity.

Outline better contractual forms

When facing unexpected eventualities, the question in regards to which party should be appointed to make key decisions always arises. By writing better contracts, it is possible for companies to define beforehand the span over which supply management practices can be subject of better contract structures to thusly motivate proper behavior within parties and the supply chain itself. It is of course something positive to provide parties with insights on their own and their counterparts’ actions.

Strive for transparency

Since the rate at which information surfs the internet has become somewhat hectic, companies are now compelled to have a closer look at their transparency initiatives mostly because people expect their products to be safe and be delivered in proper conditions. The major threat is related to the fact that companies and people often ignore whether these supply chain practices are transparent. The digital world enabled a sheer array of individuals capable of digging much deeper than expected to share a company’s darkest secrets, which, aided by social media, constitutes a major danger when it comes to wanting to thrive under such circumstances. It is now time for companies to make their processes as transparent as possible.

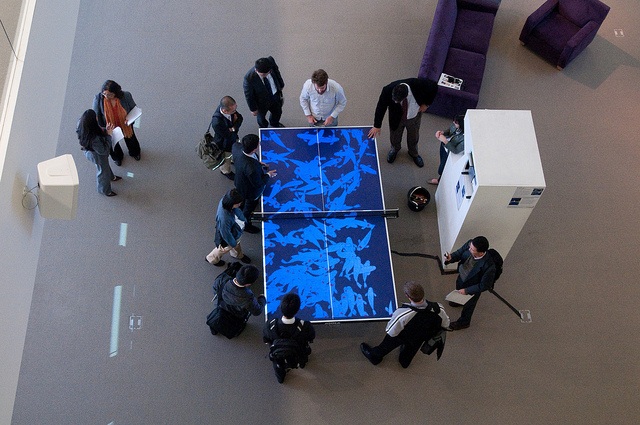

* Featured Image courtesy of josh s jackson at Flickr.com